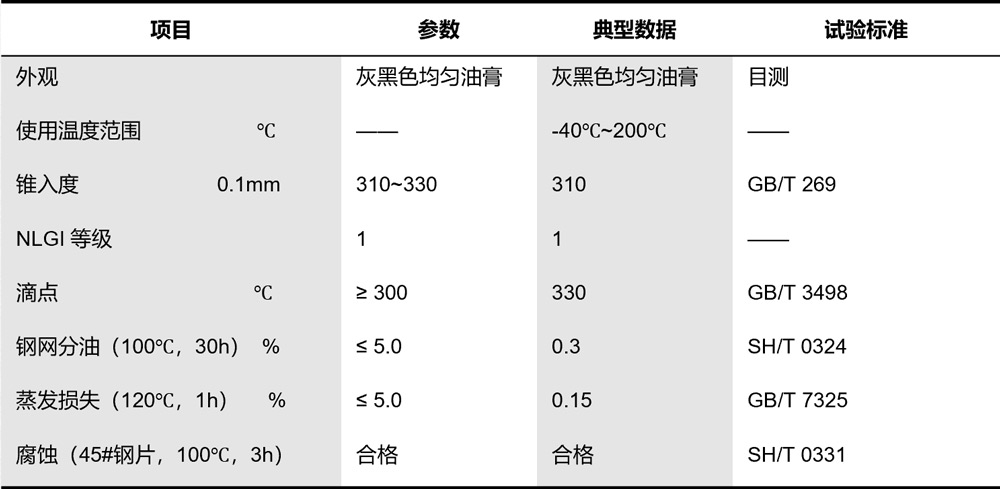

Description

Application Background

New energy vehicles use brake energy recovery technology, which results in low driving noise. The noise generated during braking becomes more prominent.

Professional anti-noise lubricant is applied between the brake pad backplate and the anti-noise shim to reduce vibration and noise generated during braking.

Lubrication Characteristics

- Brake pads for fuel vehicles and new energy vehicles, despite adjusting formulas, improving structures, and adding anti-noise shims, still generate about 10% residual noise.

- In such cases, applying professional anti-noise lubricant to the anti-noise shim can further reduce residual noise by about 90%.

Product Features

- Resistant to acid and alkali corrosion and does not corrode metal;

- Excellent performance at both high and low temperatures;

- Prevents lag, anti-seizing, and wear under high surface pressure;

- Provides long-lasting wear protection, water resistance, and prevents road grit.

Product Applications

- Automotive silencer pads;

- Drum brake moving mechanisms, adjustment screws, and back plates;

- Lubrication of various automotive deceleration plastic gears and elevator gears;

- Lubrication of regulator systems and knobs in instruments such as microscopes and telescopes.

Alibaba

Alibaba